The information you are about to read is a small excerpt from The Fields Company located in Livermore California, the link above is an educational video from the man himself explaining this tempered debris issue of which we will dig deeper into this subject below. We highly recommend you watch Dans YT video. The Fields Company is known to become the experts on scratched glass related issues due to fabricating debris or poor glass quality. We found that the thoroughness of his analysis to be extremely impressive and relevant.

I recently had the pleasure to meet Dan Fields personally and because this information is directly related to Glass we felt it necessary to forward this and hope you will pass this information on to others, especially your contractor. We are in no way affiliated with The Fields Company and receive no compensation of any kind from them whatsoever.

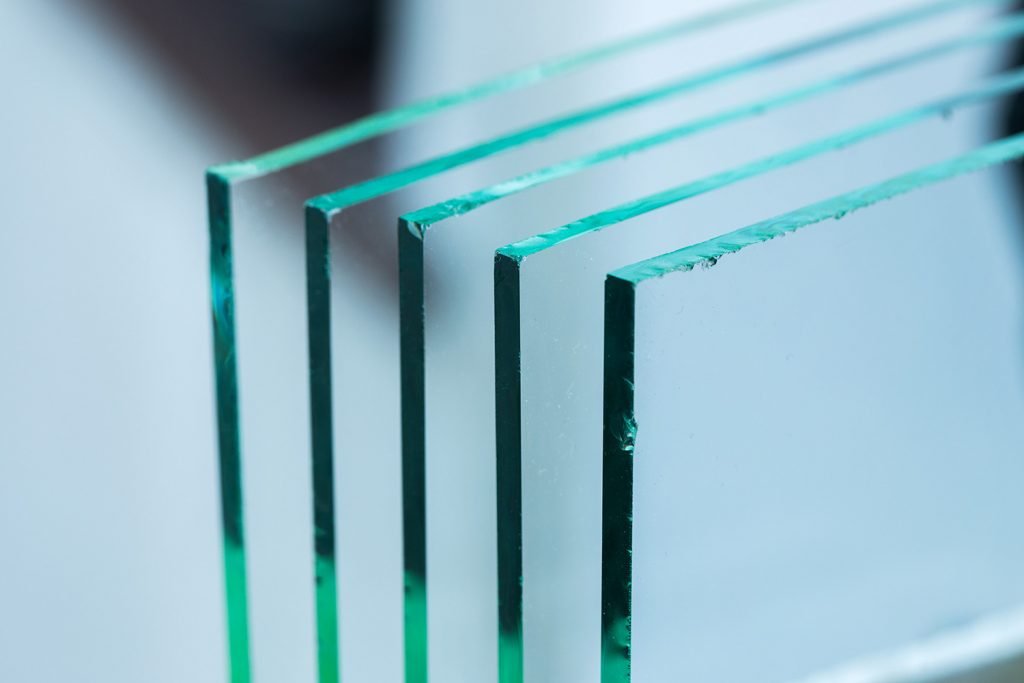

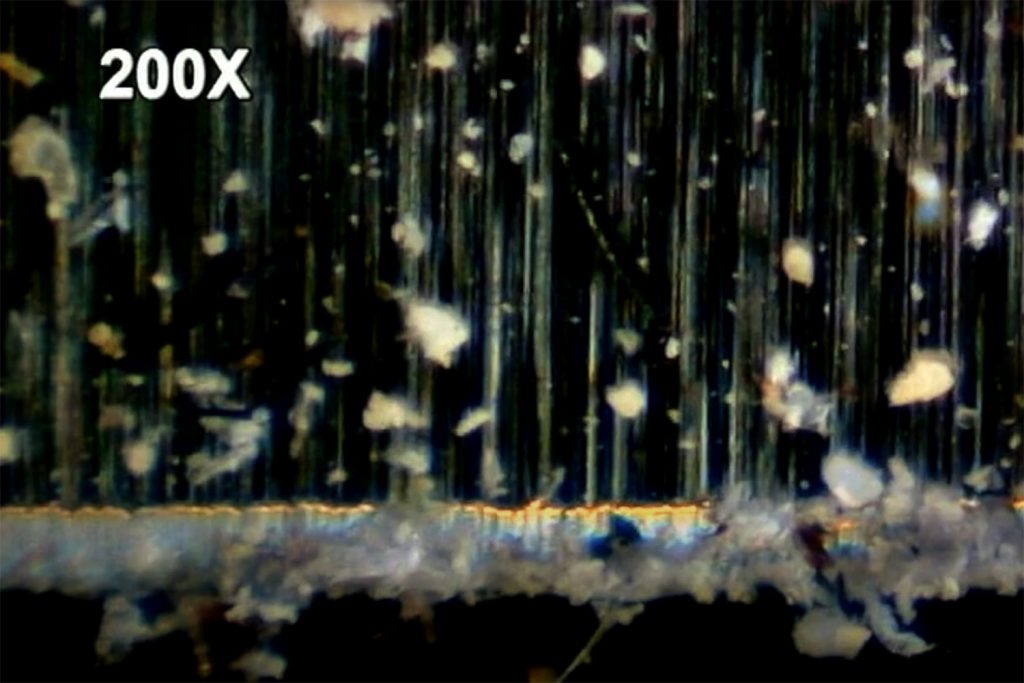

The majority of the scratches found on tempered glass result from poor glass quality. The surface quality of tempered glass will have a direct effect on the possibility of scratching the glass during cleaning. Low-quality tempered glass has fabricating debris fused to its surface, which at the time of cleaning has a very high likelihood of being dislodged and dragged across the glass surface, resulting in scratching.

Notice in this photo how each of the scratches has a clear point of origin. This point is the location where a glass particle was fused to the surface during the tempering process. This particle should have been washed from the glass before it was sent into the tempering furnace, but inadequate washing procedures allowed it to remain on the glass.

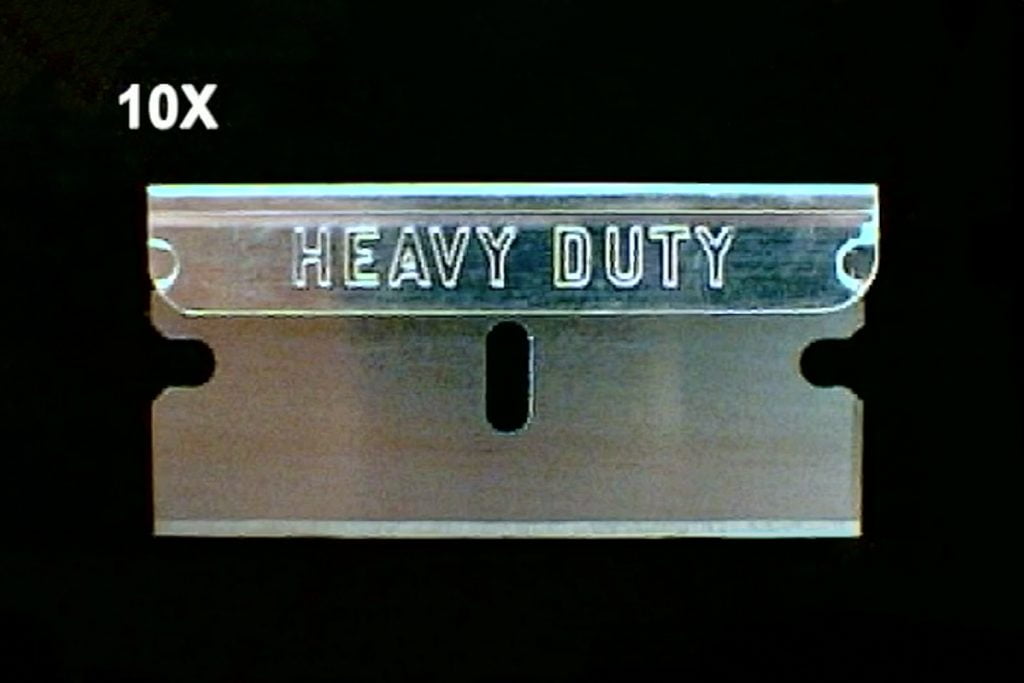

The following photos are of an isolated defect on a tempered glass sample. The sample was a factory-direct piece of glass, and was not subject to a construction environment. The after photo shows the scratch that resulted from passing a new razor blade over the glass surface. Notice how the point of origin (and therefore the cause) of the scratch is the original surface defect. The black lines on the photos are felt pen markings used to identify the location of the defect.

Single Glass Defect, Before Cleaning

Single Glass Defect, After Cleaning

New Razor Blade

New Razor Blade with Fabricating Debris

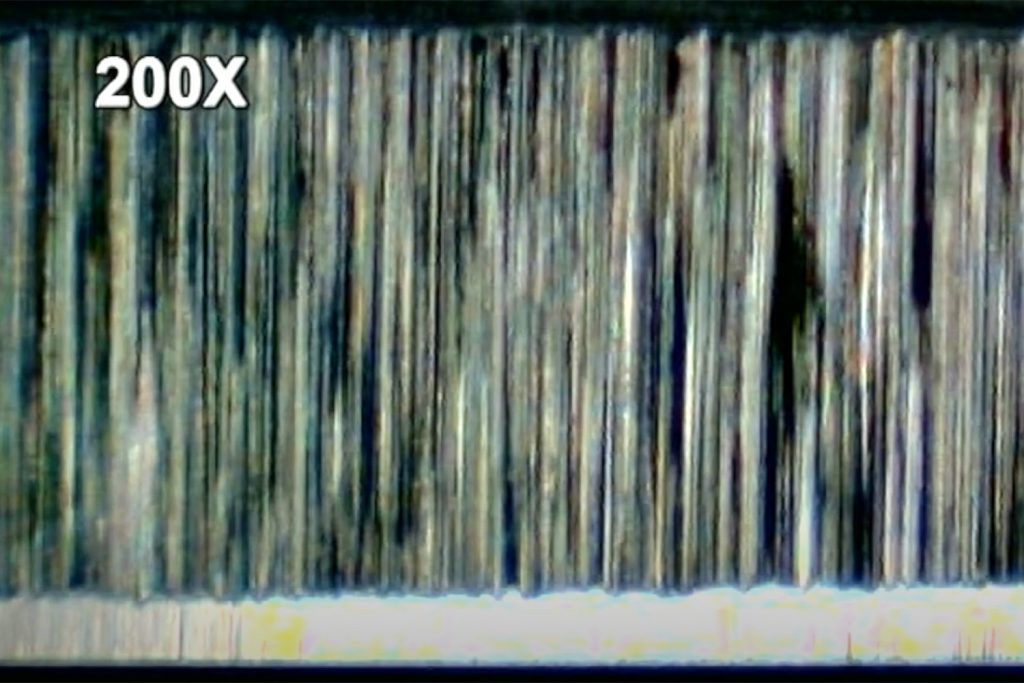

Close Up of Razor Blade Edge

Close Up of Razor Blade Edge with Fabricated Debris

Now that it’s clear why some tempered glass scratches, the next question is “Where does the fabricating debris come from?” To answer this question, we need to look back at how the tempered glass is made. The third step in the process was to wash the glass after it had been sized and ground, but not all glass manufacturers do an adequate job at this step. Most problems in this area are related to the lack of maintenance to the washer and tempering furnace. If the glass washer and tempering furnace are not properly maintained, fabricating debris will build, making them less effective in cleaning and tempering the glass.

Due to this, the glass will exit the washer with much of the fabricating debris still present as the glass is sent into the tempering furnace. Once the glass is inside the furnace, the debris will begin to liquefy and fuse itself to the roller side surface of the glass and to the furnace rollers. It is this fabricating debris that causes the poor quality surface and the scratching on defective tempered glass. When a window cleaner removes construction debris from the glass surface, they also remove these defects, which scratch the glass as they’re moved across the glass surface.

Over time, the tempering furnace will also become contaminated with fabricating debris and must be serviced to clean the furnace rollers. To date, washing glass prior to tempering is not required or enforced by any regulation or standard.

Isolated Fabricated Debris from a Defective Tempered Glass Surface

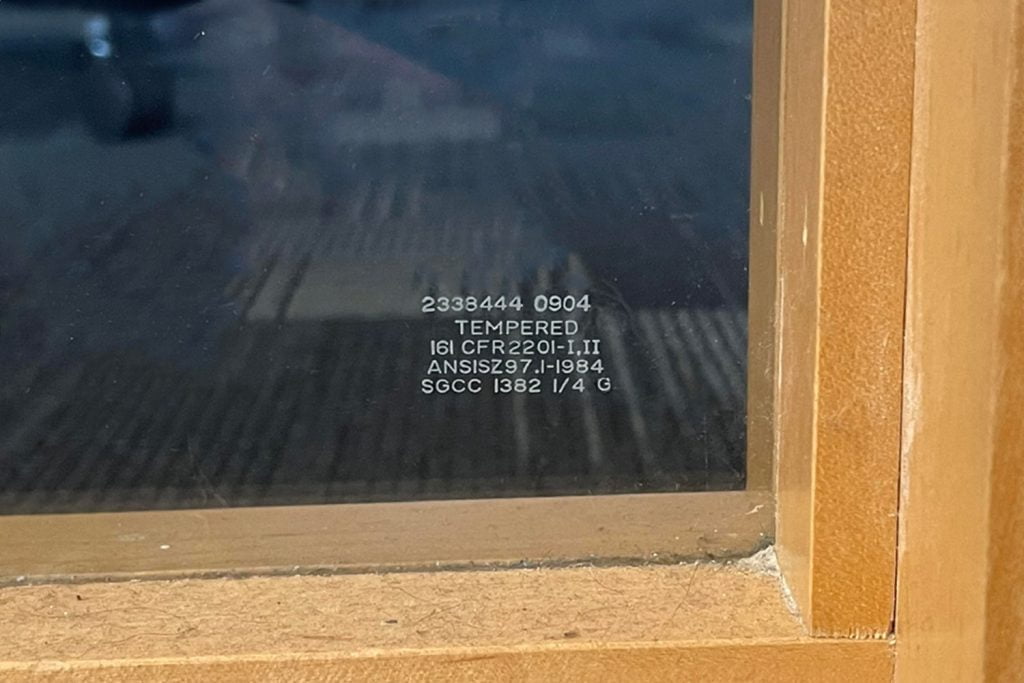

Given the location of the furnace roller relative to the glass sample is so important, it is obvious that a method of determining which side was the roller side is vital. The key to this determination is the tempering stamp. Each tempered glass manufacturer has their own tempering stamp that they put on their glass samples (see photo of tempering stamp to the left). By identifying the location of the tempering stamp, the roller side of the glass can be determined. The important part in this determination is the type of tempering stamp.

There are two major types of stamps used: sand blasted and porcelain. A sand blasted stamp is located on the roller side of the glass and will identify the potentially defective surface. A porcelain stamp is located on the side opposite the rollers and will identify the quality surface.

This is a good time to point out that tempered glass is not always installed in the proper location in a building. Sometimes, with several windows being the same size, they are mistakenly installed in the wrong location. A check for the tempering stamp is the best way to determine if the glass is truly tempered.

Clearview Sun Control, Inc.

811 N Catalina Ave. #2300

Redondo Beach, CA 90277